980M Wheel Loader

360° Exterior View

360° Interior View

At a Glance

|

|

|

|

|

|

|

|

Overview

The new 980M Wheel Loader has either a Tier 2/Stage II, Tier 3/Stage IIIA equivalent or Tier 4 Final/Stage IV, depending on emission standards of specific country, engine equipped with a combination of proven electronic, fuel, air and aftertreatment components. Applying proven technologies systematically and strategically lets us meet your high expectations for productivity and fuel efficiency. Deep system integration results in reduced emissions, improved performance and improved fuel economy without interrupting machine performance making it seamless to you. The reliability, durability, and versatility of the 980M result in a machine that is better built to meet your needs.

Engine

+ -| Net Power - ISO 9249 | 386hp |

| Net Power - ISO 9249 | 386HP |

| Engine Model | Cat® C13 ACERT™ |

| Engine Model | Cat? C13 ACERT? |

| Bore | 5.12in |

| Stroke | 6.18in |

| Displacement | 763.0in3 |

| U.S. EPA Tier 4 Final/EU Stage IV - Maximum Power - SAE J1995 | 425HP |

| Tier 2/Stage II, Tier 3/Stage IIIA Equivalent: Maximum Power – SAE J1995 | 412hp |

| Maximum Net Power (1,700 rpm) – SAE J1349 | 386.0hp |

| Maximum Net Power – SAE J1349 | 386.0hp |

| Maximum Net Torque (1,100 rpm) – SAE J1349 | 1515.0lbf-ft |

| Peak Gross Torque (1,200 rpm) – SAE J1995 | 1627.0lbf-ft |

| Emissions | Cat engine with ACERT Technology – meets Tier 4 Final emission standards. |

| Note | The power ratings apply at the stated speed when tested under the reference conditions for the specified standards. |

| Note | The net power advertised is the power available at the flywheel when the engine is equipped with fan, alternator, air cleaner and aftertreatment. |

| Note | The gross power advertised is with the fan at maximum speed. |

| Tier 2/Stage II, Tier 3/Stage IIIA Equivalent: Maximum Power - SAE J1995 | 412HP |

Weights

+ -| Operating Weight | 66337lb |

| Operating Weight | 66337lb |

| Note | For 5.4 m3 (7.1 yd3) general purpose buckets with BOCE. |

| Note | Weight based on a machine configuration with Michelin 29.5R25 XLDD1 L4 radial tires, full fluids, operator, standard counterweight, cold start, roading fenders, Product Link, open differential axles (front/rear), secondary steering, sound suppression, and |

| Note (1) | For 5.4 m3 (7.1 yd3) general purpose buckets with BOCE. |

| Note (2) | Weight based on a machine configuration with Michelin 29.5R25 XLDD1 L4 radial tires, full fluids, operator, standard counterweight, cold start, roading fenders, Product Link, open differential axles (front/rear), secondary steering, sound suppression, and |

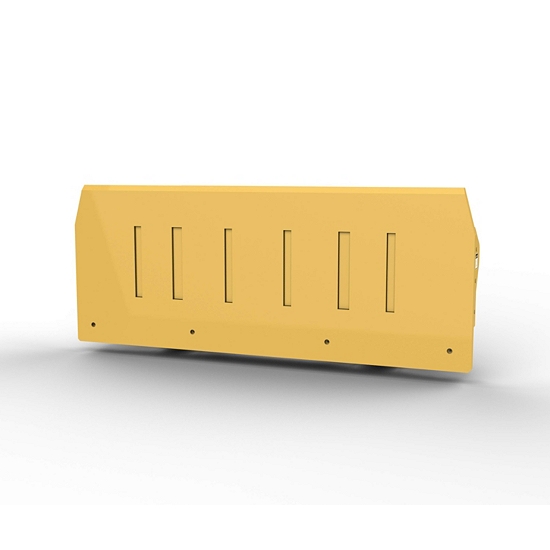

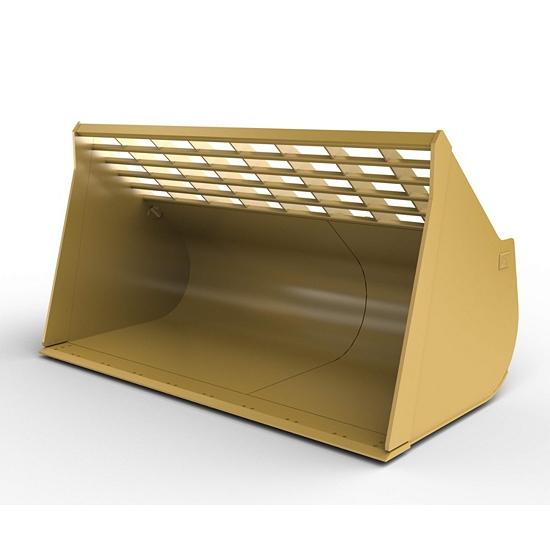

Buckets

+ -| Bucket Capacities | 4.2-12.2 m3 (5.25-16.0 yd3) |

| Bucket Capacities | 4.2-12.2 m3 (5.25-16.0 yd3) |

Transmission

+ -| Forward 1 | 4.3mph |

| Forward - 1 | 4.3mile/h |

| Forward 2 | 8.3mph |

| Forward - 2 | 8.3mile/h |

| Forward 3 | 14.6mph |

| Forward - 3 | 14.6mile/h |

| Forward 4 | 24.5mph |

| Forward - 4 | 24.5mile/h |

| Reverse 1 | 4.8mph |

| Reverse - 1 | 4.8mile/h |

| Reverse 2 | 9.4mph |

| Reverse - 2 | 9.4mile/h |

| Reverse 3 | 16.7mph |

| Reverse - 3 | 16.7mile/h |

| Reverse 4 | 24.5mph |

| Reverse - 4 | 24.5mile/h |

| Note | Maximum travel speed in standard vehicle with empty bucket and standard L4 tires with 933 mm (37 in) roll radius. |

| Note | Maximum travel speed in standard vehicle with empty bucket and standard L4 tires with 933 mm (37 in) roll radius. |

Axles

+ -| Front | Fixed |

| Front | Fixed |

| Rear | Oscillating ±13 degrees |

| Rear | Oscillating ?13 degrees |

| Maximum Single-Wheel Rise and Fall | 1.87ft |

| Maximum Single-Wheel Rise and Fall | 1.87ft |

Brakes

+ -| Brakes | Brakes meet ISO 3450:2011 standards |

| Brakes | Brakes meet ISO 3450:2011 standards |

Cab

+ -| ROPS/FOPS | ROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards |

| ROPS/FOPS | ROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards |

Operating Specifications

+ -| Breakout Force | 50357lbf |

| Breakout Force | 50357lb |

| Static Tipping Load – Full 40° Turn: No Tire Deflection | 45847lb |

| Static Tipping Load – Full 40° Turn: With Tire Deflection | 43133lb |

| Note | Full compliance to ISO (2007) 143971 Sections 1 thru 6, which requires 2% verification between calculations and testing. |

| Static Tipping Load - Full 40° Turn - No Tire Deflection | 45847lb |

| Static Tipping Load - Full 40° Turn - With Tire Deflection | 43133lb |

| Note | Full compliance to ISO (2007) 143971 Sections 1 thru 6, which requires 2% verification between calculations and testing. |

Hydraulic System

+ -| Hydraulic Cycle Time - Rated Payload - Dump, at Maximum Raise | 1.7s |

| Hydraulic Cycle Time - Rated Payload - Lower, Empty, Float Down | 3.1s |

| Hydraulic Cycle Time - Rated Payload - Raise from Carry Position | 5.3s |

| Hydraulic Cycle Time - Rated Payload - Total | 10.1s |

| Implement Pump Type | Variable Displacement Piston |

| Implement System - Maximum Operating Pressure | 4975psi |

| Implement System: Maximum Pump Output (2,250 rpm) | 119gal/min |

| Implement System: Optional 3rd Function Maximum Flow | 63gal/min |

| Implement System: Optional 3rd Function Maximum Pressure | 3159psi |

| Implement System - Maximum Pump Output at 2,250 rpm | 119gal/min |

| Implement System - Optional 3rd Function Maximum Flow | 63gal/min |

| Implement System - Optional 3rd Function Maximum Pressure | 3159psi |

Service Refill Capacities

+ -| Cooling System | 14.0gal |

| Crankcase | 9.8gal |

| Transmission | 20.3gal |

| Differentials and Final Drives – Front | 22gal |

| Differentials and Final Drives – Rear | 22gal |

| Hydraulic Tank | 40gal |

| DEF Tank | 5.5gal |

| Fuel Tank | 112.5gal |

| Cooling System | 14gal (US) |

| Crankcase | 9.8gal (US) |

| DEF Tank | 5.5gal (US) |

| Differential - Final Drives - Front | 22gal (US) |

| Differential - Final Drives - Rear | 22gal (US) |

| Fuel Tank | 112.5gal (US) |

| Hydraulic Tank | 40gal (US) |

| Transmission | 20.3gal (US) |

Sound (Tier 2/Stage II, Tier 3/Stage IIIA equivalent)

+ -| Exterior Sound Power Level (ISO 6395:2008)* | 112dB(A) |

| Exterior Sound Pressure Level (SAE J88:2013)** | 78dB(A) |

| Note | The sound values indicated are for specific operating conditions only. Machine and operator sound levels will vary at different engine and/or cooling fan speeds. Hearing protection may be needed when the machine is operated with a cabin that is not proper |

| Note | *For a standard machine configuration, measured according to the procedures specified with the cooling fan speed set at maximum value. |

| Note | **For a standard machine configuration, measured according to the procedures specified. The measurement was conducted under the following conditions: distance of 15 m (49.2 ft), moving forward in second gear ratio with the cooling fan speed set at maximum |

Sound

+ -| Note | The sound values are for specific operating conditions only. |

Sound - Tier 2/Stage II, Tier 3/Stage IIIA Equivalent

+ -| Operator Sound Pressure Level - ISO 6396:2008 | 75dB(A) |

| Exterior Sound Power Level - ISO 6395:2008* | 112dB(A) |

| Exterior Sound Pressure Level - SAE J88:2013** | 78dB(A) |

| Note (1) | The sound values indicated are for specific operating conditions only. Machine and operator sound levels will vary at different engine and/or cooling fan speeds. Hearing protection may be needed when the machine is operated with a cabin that is not proper |

| Note (2) | *For a standard machine configuration, measured according to the procedures specified with the cooling fan speed set at maximum value. |

| Note (3) | **For a standard machine configuration, measured according to the procedures specified. The measurement was conducted under the following conditions: distance of 15 m (49.2 ft), moving forward in second gear ratio with the cooling fan speed set at maximum |

Engine - Tier 2/Stage II, Tier 3/Stage IIIA Equivalent

+ -| Engine Model | Cat C13 ACERT |

| Maximum Power - 1,800 rpm - SAE J1995 | 417HP |

| Maximum Net Power - 1,800 rpm - SAE J1349 | 373HP |

| Peak Gross Torque - 1,300 rpm - SAE J1995 | 1617ft·lbf |

| Maximum Net Torque - 1,000 rpm - SAE J1349 | 1505ft·lbf |

| Bore | 5.12in |

| Stroke | 6.18in |

| Displacement | 763in³ |

| Emissions | Cat engine with ACERT Technology ? meets Tier 2/Stage II, Tier 3/Stage IIIA equivalent emission standards. |

Engine (Tier 4 Final/Stage IV)

+ -| Engine Model | Cat C13 ACERT |

| Maximum Net Power (1,700 rpm) – SAE J1349 | 386hp |

| Peak Gross Torque (1,200 rpm) – SAE J1995 | 1627lbf-ft |

| Maximum Net Torque (1,100 rpm) – SAE J1349 | 1515lbf-ft |

| Bore | 5.12in |

| Stroke | 6.18in |

| Displacement | 763in3 |

| Emissions | Cat engine with ACERT Technology – meets Tier 4 Final/Stage IV emission standards. |

| Note | The power ratings apply at the stated speed when tested under the reference conditions for the specified standards. |

| Note | The net power advertised is the power available at the flywheel when the engine is equipped with fan, alternator, air cleaner and aftertreatment. |

| Note | The gross power advertised is with the fan at maximum speed. |

Engine - Tier 4 Final/Stage IV

+ -| Maximum Power - 1,700 rpm - SAE J1995 | 425HP |

| Bore | 5.12in |

| Displacement | 763in³ |

| Emissions | Cat engine with ACERT Technology ? meets Tier 4 Final/Stage IV emission standards. |

| Engine Model | Cat C13 ACERT |

| Maximum Net Power - 1,700 rpm - SAE J1349 | 386HP |

| Maximum Net Torque - 1,100 rpm - SAE J1349 | 1515ft·lbf |

| Note (1) | The power ratings apply at the stated speed when tested under the reference conditions for the specified standards. |

| Note (2) | The net power advertised is the power available at the flywheel when the engine is equipped with fan, alternator, air cleaner and aftertreatment. |

| Note (3) | The gross power advertised is with the fan at maximum speed. |

| Peak Gross Torque - 1,200 rpm - SAE J1995 | 1627ft·lbf |

| Stroke | 6.18in |

Sound - Tier 4 Final/Stage IV

+ -| Note (1) | The sound values indicated are for specific operating conditions only. Machine and operator sound levels will vary at different engine and/or cooling fan speeds. Hearing protection may be needed when the machine is operated with a cabin that is not proper |

| Operator Sound Pressure Level - ISO 6396:2008 | 72dB(A) |

| Exterior Sound Power Level - ISO 6395:2008* | 112dB(A) |

| Exterior Sound Pressure Level - SAE J88:2013** | 78dB(A) |

| Note (2) | *For a standard machine configuration, measured according to the procedures specified with the cooling fan speed set at maximum value. |

| Note (3) | **For a standard machine configuration, measured according to the procedures specified. The measurement was conducted under the following conditions: distance of 15 m (49.2 ft), moving forward in second gear ratio with the cooling fan speed set at maximum |

Standard Equipment:

Operator Environment

+ --

Cab, pressurized and sound suppressed (ROPS/FOPS)

-

Viscous mounts

-

Multi-function 18 cm (7 in) color LCD touch-screen display for rear vision camera and machine parameters.

-

Electro-hydraulic controls, SAL (single axis lever) lift and tilt function

-

Steering, electro-hydraulic joystick, speed sensing with force feedback

-

Radio ready (entertainment) includes antenna, speakers and converter (12V, 10-amp)

-

Air conditioner, heater, and defroster (auto temp and fan)

-

Electro-hydraulic parking brake

-

Beverage holders (2) with storage compartment for cell phone/MP3 player

-

Bucket/work tool function lockout

-

Coat hook (2)

-

Cab air filter

-

Ergonomic cab access ladders and handrails

-

Horn, electric

-

Light, two dome (cab)

-

Mirrors, rearview external with integrated spot mirrors

-

Post mounted membrane 16 switch keypad

-

3 receptacles, 12V

-

Seat, Cat Comfort (cloth) air suspension

-

Seat belt, 51 mm (2 in) retractable, with indicator

-

Sun visor, front

-

Wet-arm wipers/washers front and rear, intermittent front wiper

-

Window, sliding (left and right sides)

-

Cab tie-off

Computerized Monitoring System

+ --

With following gauges: – Speedometer/tachometer – Digital gear range indicator – Diesel Exhaust Fluid (DEF) level – Temperature: engine coolant, hydraulic oil, transmission oil – Fuel level

-

With following warning indicators: – Regeneration – Temperature: axle oil, engine intake manifold – Pressure: engine oil, fuel pressure hi/low, primary steering oil, service brake oil – Battery voltage hi/low – Engine air filter restriction – Hydraulic oi

Electrical And Lighting

+ --

Batteries (2), maintenance free 1,400 CCA

-

Ignition key; start/stop switch

-

Starter, electric, heavy duty

-

Starting and charging system (24V)

-

Lighting system: – Four halogen work lights (cab mounted) – Two halogen roading lights (with signals) – Two halogen rear vision lights (hood mounted)

-

Alarm, back-up

-

Alternator, 145-amp brushed

-

Main disconnect switch

-

Receptacle start (cables not included)

Cat Connect Technologies

+ --

Link technologies: Product Link

-

Detect technologies: rear vision camera

Power Train

+ --

Engine, Cat C13 ACERT – meets Tier 2/Stage II, Tier 3/Stage IIIA equivalent or Tier 4 Final/Stage IV emission standards

-

Cat Clean Emissions Module (CEM) with Diesel Particulate Filter (DPF) and remote Diesel Exhaust Fluid tank and pump

-

Fuel priming pump (electric)

-

Fuel/water separator

-

Precleaner, engine air intake

-

Economy mode (selectable)

-

Transmission, automatic planetary power shift (4F/4R)

-

Torque converter, locking clutch with free wheel stator

-

Switch, transmission neutralizer lockout

-

Axles, open differential, front and rear

-

Axles, ecology drains

-

Brakes, full hydraulic enclosed wet-disc with Integrated Braking System (IBS)

-

Brake wear indicators

-

Parking brake, disc and caliper

-

Fan, radiator, on demand

Linkage

+ --

Linkage, Z-bar, cast crosstube/tilt levers

-

Kickout, lift and tilt, automatic (adjustable in cab)

Hydraulics

+ --

Hydraulic system, load sensing

-

Steering, load sensing

-

Ride control, 2V

-

Remote diagnostic pressure taps

-

Hoses, Cat XT™

-

Couplings, Cat O-ring face seal

-

Hydraulic oil cooler (swing out)

-

Oil sampling valves

Fluids

+ --

Premixed extended life coolant with freeze protection to –34° C (–29° F)

Other Standard Equipment

+ --

One-piece tilting hood with side and rear doors

-

Service centers (electrical and hydraulic)

-

Platform, window washing

-

Auto idle shutdown

-

Fenders, non-metallic front with mud-flap/rear with extension

-

Ecology drains for engine, transmission, and hydraulics

-

Ether aid ready

-

Grill, airborne debris

-

Filters: fuel, engine air, engine oil, hydraulic oil, transmission

-

Fuel cooler

-

Grease zerks

-

Hitch, drawbar with pin

-

Precleaner rain cap

-

Sight gauges: engine coolant, hydraulic oil, and transmission oil level

-

Toolbox

-

Vandalism protection caplocks

Optional Equipment:

Operator Environment

+ -Door, remote opening system

Cover, HVAC metallic

EH controls, SAL 3rd function

EH controls, joystick lift and tilt: – Additional integrated roller switch for 3rd function

Filter, carbon fresh air

Mirrors, heated rearview external with integrated spot mirrors

Precleaner, HVAC

Precleaner, HVAC (RESPA)

Radio, AM/FM/USB/MP3 Bluetooth

Radio, AM/FM/CD/USB/MP3 Bluetooth

Radio, AM/FM/CD/USB/MP3 Bluetooth with Satellite Sirius and XM

Radio, CB ready

Seat, heated air suspension

Seat belt, 76 mm (3 in) retractable, with indicator

Steering, EH wheel with directional FNR shifter and gear selector: – Additional FNR with implement controls

Roof, metallic

Steering, secondary

Sun visor, rear

Windows, rubber mounted

Windows, with front guard

Windows, with heavy duty front guard

Windows, with full guards front, rear and sides

Electrical And Lighting

+ -Four additional auxiliary halogen cab mounted work lights or

Two additional auxiliary front HI LED and two additional auxiliary rear LED cab mounted work lights with two LED work lights in the radiator grill and LED front turn signals also includes replacement of the standard four halogen cab mounted work lights wi

Warning amber strobe beacon

Reversing strobes

External seat belt indicator light

Speed limiter – 20 km/h (Europe only)

Starters, Batteries, And Alternators

+ -Batteries (4), maintenance free 1,400 CCA with 120V engine coolant heater

Batteries (4), maintenance free 1,400 CCA with 240V engine coolant heater

Cat Connect Technologies

+ -Payload technologies: – Advanced Productivity subscription – Cat Production Measurement 2.0 – Printer – Aggregate Autodig

Detect technologies: – Cat Rear Object Detection

Machine Security System

Power Train

+ -Axles: – Limited slip differentials, front and/or rear – Axle oil cooler – Extreme temperature seals

Heavy duty transmission

Fan, VPF (variable pitch fan), automatic and manual control

Radiator, high debris with wider fin spacing

Linkage

+ -High lift

Logger

Quick coupler ready

Work Tools

+ -Performance Series buckets

Forks, pallet

Forks, logging

Hydraulics

+ -3rd function with Ride Control: – Standard linkage – High lift linkage – Logger linkage

Fluids

+ -Premixed extended life coolant with freeze protection to –50° C (–58° F)

Other Optional Equipment

+ -Cat Autolube System

Wheel chocks

Fenders, roading

Guard, power train

Oil change, high speed engine

Fuel tank, fast fill

Precleaner, turbine

Precleaner, trash

Other Optional Configurations

+ -Aggregate Handler

Industrial and Waste Handler

Logger

Steel Mill