6 Types of Water Pumps for Construction Jobs

Water pumps are useful for moving liquids to and from a site. Whether your company is responsible for building structures or servicing underground plumbing connections, having the right tools on hand allows you to perform jobs with fewer interruptions. There are numerous types of water pumps used within the construction industry, so selecting the appropriate one for your applications will help you complete tasks safely and according to your time frame.

If you’re wondering which water pump type will best suit your needs, review the information below to get a better idea of the differences between common configurations.

What Are the Different Types of Water Pumps?

Construction companies specialize in different areas. Since there is no one-size-fits-all water pump solution, decision-makers want to choose a water pump build based on the viscosity of liquids workers will be handling and flow rates for a given job. You can find dozens of water pumps used in construction fields, but the most popular options are as follows.

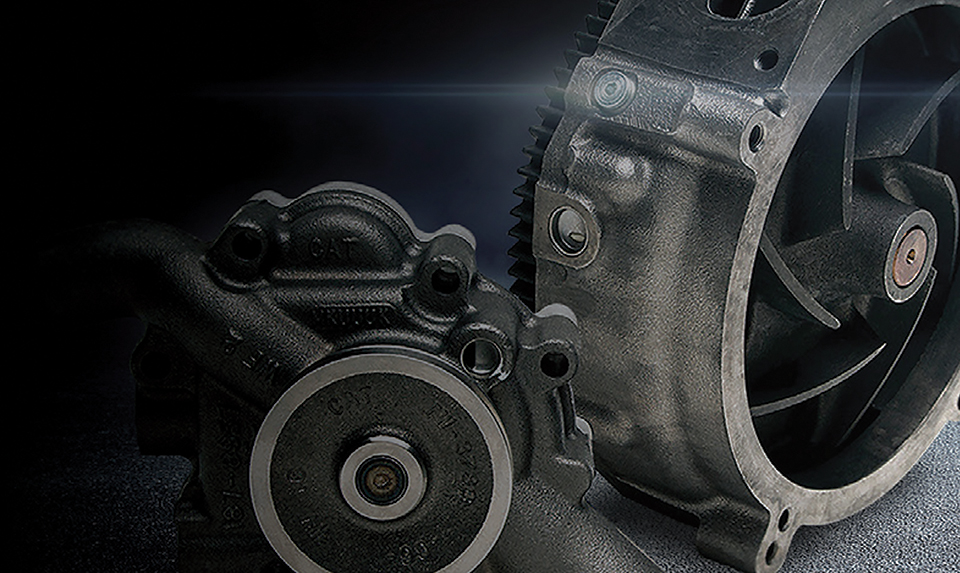

1. Centrifugal Pumps

Centrifugal water pumps are assemblies that have at least one impeller. These water pumps are powered by an electric motor to move water to a different location. As one or more impellers spin, liquids flow through the pump, where they are exposed to vast amounts of pressure for redirection. Construction crews utilize centrifugal pumps for liquids with high and low viscosities. These pumps are excellent for moving lean liquids with a high flow rate.

Centrifugal water pumps are widely used in the construction industry, as they are effective for draining groundwater as well as bringing water supplies to building grounds. Professionals might use a centrifugal water pump to configure emergency fire systems or sump pump installations since they can handle clean and polluted liquids with consistent pressure. Centrifugal water pumps work best with thinner liquids as opposed to oils that can cause clogs.

2. Positive Displacement Pumps

Positive displacement water pumps are also used for water relocation. However, the technology relies on an internal diaphragm to trap liquids in specific volumes before anything moves through discharge piping. Positive displacement pumps do not have impellers, and assemblies push a consistent volume of water through the system using internal components that expand and contract. This type of water pump is widely used in construction for high-viscosity liquids.

Construction businesses look to positive displacement pumps for jobs with strict deadlines. These systems are well-known for their ability to remove air from connections without the need for operators to bleed air manually. Positive displacement water pumps are used in situations where sensitive solids are present in water. Equipment operators can control the direction of water with flow rates lower than centrifugal pumps.

3. Booster Water Pumps

A booster water pump is designed for a centrifugal pump system. As the name implies, the technology is responsible for increasing pressure at specific points. The systems feature multiple impellers to help construction workers move water over far distances in less time than a standard centrifugal pump.

Booster water pumps are primarily used for potable water sources. For example, a crew might use this type of pump to deliver drinking water to a new building structure. Another application of booster water pumps includes maximizing water pressure for irrigation systems. Booster water pumps are unsuitable for liquids containing fine solids.

4. Axial Flow Pumps

Axial flow pumps are engineered for extremely high flow rates. Impellers installed on axial flow pumps are set to operate at intense speeds to remove water from construction sites as quickly as possible. Construction businesses should consider utilizing these industrial high-pressure water pumps after experiencing inclement weather storms to the point where serious flooding takes place. Your team can redirect water with or without fine solids as long as the pump has an impeller rated for the job at hand.

5. Chopper Pumps

A chopper pump is necessary when construction crews have to relocate water that may consist of dirt, mud, debris and sediment. This type of centrifugal pump is equipped with powerful grinding teeth to shred fine solids making their way through the system. If a project involves standing water that could cause a backup, chopper pumps get the job done with minimal complications. It’s best to utilize a chopper pump anytime wastewater is involved with a building, draining or demolition assignment.

6. Trash Pumps

Trash pumps are some of the most rugged submersible water pumps on the market. These systems can move water from trenches, mines and other areas that have rocks and abrasive materials. Trash pumps have specially designed impellers that reduce the chances of clogs, and their internal seals are reinforced for durability. Construction companies that handle land clearing operations benefit from trash pumps, as the equipment processes gravel, stone, pollution, leaves and sticks.

The Importance of Selecting a Quality Pump

Choosing the right water pump for your construction applications requires some research. Selecting a build manufactured with long-lasting materials saves you from costly repairs down the road.

First, check to see that a water pump is from a reputable manufacturer. You’ll also want to investigate the engine specifications to ensure you have enough power to complete daily tasks in a reasonable amount of time. A quality water pump can last thousands of hours with preventive maintenance. Opting for a build from an established manufacturer makes it easy to find replacement parts if you need them down the road. Lastly, decision-makers should purchase water pumps with cast iron impellers if employees redirect water with solids present. Water pumps featuring a stainless steel or die-cast aluminum exterior housing resist corrosion for consistent performance.

Purchase Water Pumps From Cleveland Brothers

At Cleveland Brothers, we sell, rent and service portable water pumps including Atlas Copco, Godwin and more to construction professionals in central Pennsylvania, western Maryland and northern West Virginia. With competitive pricing and financing plans, we make it easy for you to get the equipment you need to take on new opportunities in your field.

If you have any questions about the types of water pumps we have for sale, contact the Cleveland Brothers team today.

This content is created and reviewed by the Cleveland Brothers team. With nearly 75 years of experience in the heavy equipment industry, our team offers the expertise and skill you need to finish the job. Contact our team today for more information on new and used equipment.