Screens

- products

- new products

- aggregate equipment

- screens

Screening by using geometrical patterns – bars, wire, circle, square or rectangle – is the most common method of size control in aggregates processing. We offer screens for both wet and dry applications, and the screening media for optimum end product quality. Our equipment is easily adaptable for stationary and mobile crushing plants

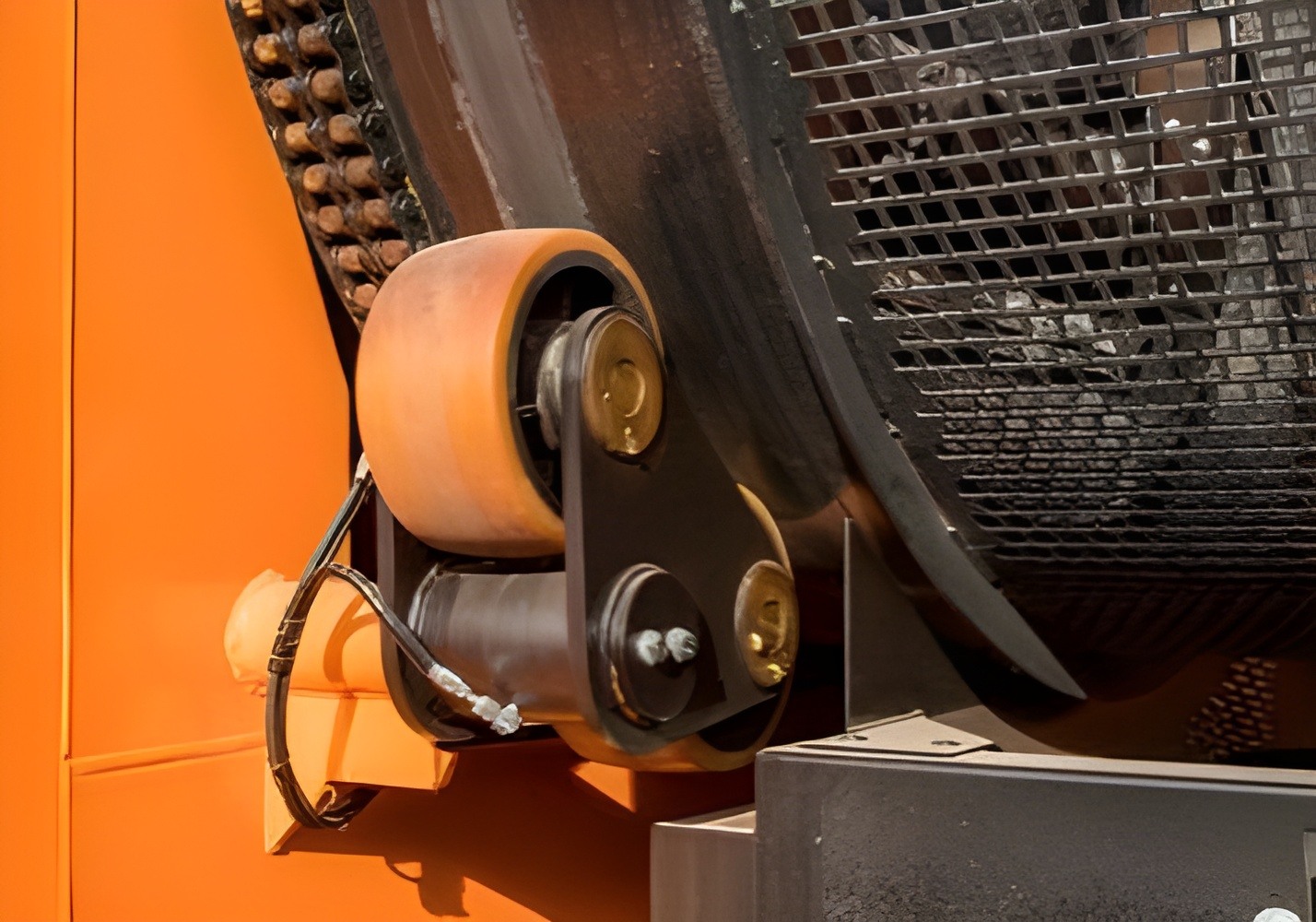

EcoScreen Duplex 52 Double Trommel Screen

Chassis:

Steel tracks

Drive:

CAT C3.6 74 - Tier 4 Final

Power:

100HP

Fuel Tank:

52 gallons

Ecosift Aeras Windsifter

CHASSIS:

Robust steel construction

DRIVE:

Hydraulically driven via other unit such as a Doppstadt SM trommel or other compatible unit. Also Available in Electric Drive

POWER:

Required

SUCTION HOSE:

• Diameter: 16” • Included: 25’ of hose

Metso Outotec ST2.8

Screen size:

4,860 x 1,520 mm (16’ x 5’)

Screening area:

7.4 m2 (79 ft2)

Screening working angle:

10-17°

Decks:

2

Metso Outotec ST4.10

Screen size:

6,000 x 1,520 mm (20’ x 5’)

Screening area:

9 m2 (100 ft2)

Screening working angle:

18-30°

Decks:

3

Nordtrack S2.11

Top deck:

6,100 x 1,800 m (20’ x 6’)

Bottom deck:

5,500 x 1,800 m (18’ x 6’)

Stroke:

10 mm

Hopper capacity:

11.5 m3 (15.0 yd3)

Doppstadt SM 617.2 Trommel Screen

Chassis:

Central axle

Drive:

Diesel Engine - Deutz TCD 2.9 L4. EPA Tier 5 Final

Power:

75HP (55kW)

Fuel Tank:

80 gallons

Doppstadt SM 726.2 SA Trommel Screen

Chassis:

Fifth wheel, two axles

Drive:

Diesel Engine - Deutz TCD 3.6 L4. EPA Tier 5 Final

Power:

114HP (85kW)

Fuel Tank:

106 gallons

ST2.8 Locotrack Mobile Scalping Screen

Engine:

CAT®, 75 / 98 / 106 kW (100 / 131 / 142 hp)

Screen size:

4 866 x 1 524 mm (16’ x 5’)

Feed hopper:

4.5 m³ (5.9 yd³)

Weight:

26 000 kg (57 000 lbs)