Machining & Fabrication Services – CB HYMAC Camp Hill, PA

We know that you have components that require precise capabilities. We’re here to deliver custom services to help boost your productivity and profits. Cleveland Brothers has a hydraulics, machining and chroming division—CB HYMAC—that is dedicated to providing you with custom fabrication, welding and machining services for your components and machines.

The Camp Hill, Pa., facility of CB HYMAC holds the API Spec Q1 and ISO 9001:2015 certifications for its quality management system from the American Petroleum Institute (API). The scope of this registration and the approved quality management system applies to the hydraulic cylinder repair, rebuilding, machining, laser cladding, hard chrome plating, welding and component re-manufacturing capabilities at Camp Hill.

CB HYMAC offers a variety of custom fabrication options for metal components, hydraulic hoses and fittings, and more. To help ensure you have precisely the parts you need, we can custom fabricate cylinders and hydraulic hoses and fittings to exact specifications. Our in-house engineers use industry-leading CAD software to ensure accuracy on any custom fabrication and pattern cutting processes.

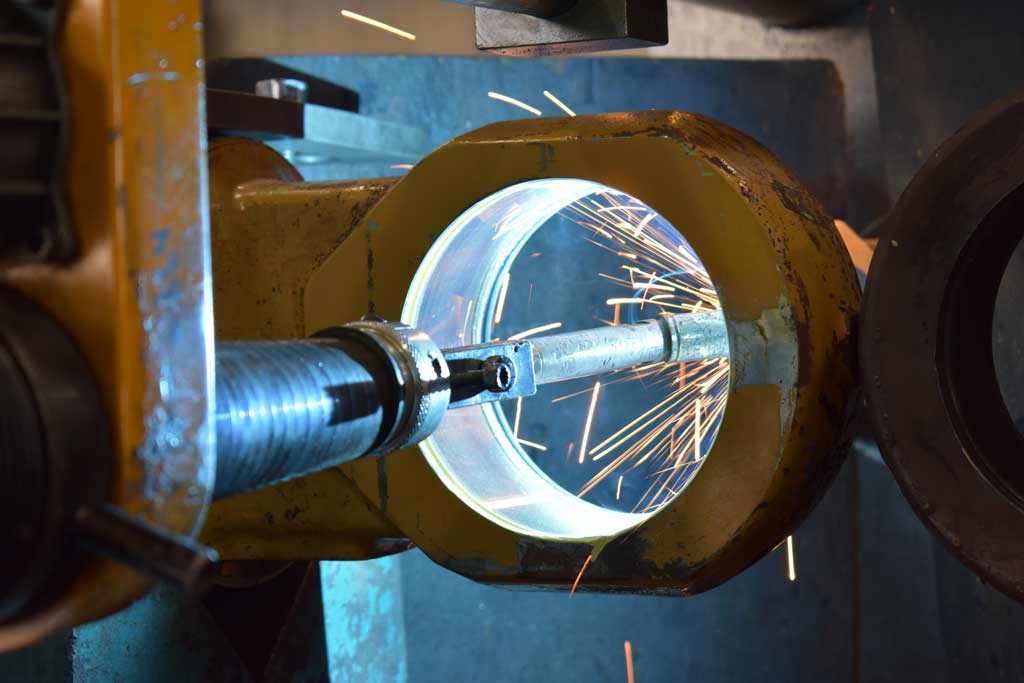

In addition, CB HYMAC offers honing machine services, reconditioning, boring up to 48 in. and more. We will work with you to meet your precise requirements. With a large machining capacity of up to 11 ft. in width and seven ft. in height, no job is too large for CB HYMAC

Welding and Fabricating Services – Blawnox, PA

Cleveland Brothers is your one safe source for all your fabricating needs. Our state of the art facilities in Pittsburgh and Harrisburg are designed to provide a full range of welding, fabricating and machining services. Our commitment is to get your job done competitively, quickly and effectively. This commitment is reflected in our people and our resources.

Cleveland Brothers provides the capabilities to support turnkey services for your fabrication needs. These include in-house engineering and design assistance, a large material inventory and a network of facilities to ensure rapid turnaround, competitive pricing and the highest quality standards. For assistance on your next welding and fabricating project contact your Product Support Representative or call 1-866-551-4602 today.

Skilled welders and machinists operate with the unique experience of having worked on equipment and components such as yours, hundreds and in some cases even thousands of times before. Our dedication to maintaining the highest quality standards in the industry is unmatched in the market. Cleveland Brothers features computer controlled, automatic burning tables capable of cutting carbon steel plates up to 12 inches thick. All Cleveland Brothers welders are fully certified and capable of welding on carbon, stainless, aluminum, copper and alloy steels.

Through precision welding and machining steps, Cleveland Brothers can recondition a wide range of expensive components at a considerable savings over the cost of new. Salvaging operations for transmission-shaft-bearing-surfaces, rear-differential-trunnions, turbo-exhaust-housings, pump-shaft-seal-surfaces, yokes and similar components can in fact be reconditioned to specifications equal to or sometimes even better than new.

- Conventional & Specialty Buckets

- Rebuilds and Repairs

- Blades

- Roller Frames

- Undercarriage rollers and idlers

- Track assembly

- Track-shoe re-grousering

- PIN and bushing turns

- Compactor wheels rebuilt

- Asphalt Rollers reshelled