Hydraulic and Machining Services

As a division of Cleveland Brothers, CB HYMAC is a facility for custom machining, fabrication and chroming services. Our hydraulic repair shop provides full-service for cylinders, pumps and motors or salvage repair services for damaged heavy equipment and industrial components. We offer Cat® standard certified repairs and rebuilds, and we use genuine Cat parts when applicable. Our services have exclusive access to Caterpillar technical support, and we provide on-site repairs and diagnostics.

The Camp Hill, Pa., facility of CB HYMAC holds the API Spec Q1 and ISO 9001:2015 certifications for its quality management system from the American Petroleum Institute (API). The scope of this registration and the approved quality management system applies to the hydraulic cylinder repair, rebuilding, machining, laser cladding, hard chrome plating, welding and component re-manufacturing capabilities at Camp Hill.

CB HYMAC is also a Caterpillar certified rebuild center and a contaminant-free facility. We provide our clients with a high level of cleanliness while delivering you services with the best tools, processes and technicians. CB HYMAC frequently passes audits to ensure regulated requirements.

Hydraulic Services

Recognized as a Cat Component Rebuild Center, CB HYMAC provides repair services to industries such as mining, railroad, construction and many others. We understand how critical it is to maintain reliable hydraulic systems when you depend on your equipment day in and day out — that’s why CB HYMAC is your local repair service provider.

Our skilled technicians offer detailed inspections of every hydraulic component found on your machine. We locate the hard-to-find replacement parts with ease, offer a warranty on each repair service and ensure our components are genuine Cat parts whenever applicable.

Our experienced technicians have remanufactured more than 2,000 types of cylinders, valves and pumps, making it clear we dedicate ourselves to helping you receive the best assistance. We also provide standard emulsion fluid testing up to 10,000 psi so you can ensure your fluid analysis is inspected at regular intervals.

CB HYMAC employs 60 well-trained experts to perform compression, load testing, and repair. Other hydraulic services we provide include:

- Pump and motor manufacturing and repair

- Cylinder manufacturing and repair

- Hammer repairs and rebuilds

- Valve reconditioning

- Hose servicing

We administer exceptional support and are confident in our certified Cat standards to get the job done.

To find out more about how CB HYMAC provides high-quality hydraulic services, visit our website.

Machining Services

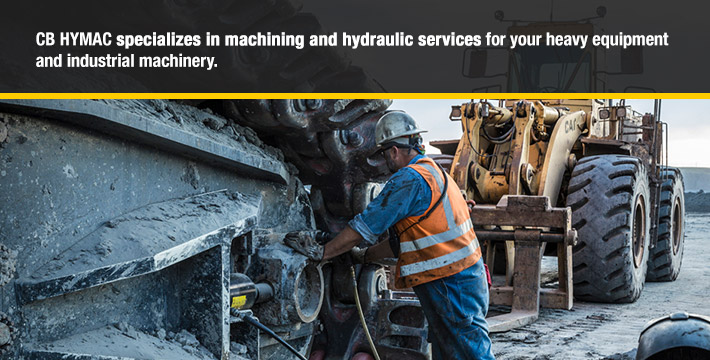

CB HYMAC specializes in machining and hydraulic services for your heavy equipment and industrial machinery. Our commitment to getting the job done efficiently, quickly and competitively are upheld throughout our CB HYMAC division.

At CB HYMAC, we are experts at machining for heavy iron and metal applications for the construction, oil and gas, railroad, mining and industrial environments. Whether it’s simple or complex machining, our facilities offer the best technology and engineers to get the job done right and precise. You can trust CB HYMAC to deliver high quality, high performing products.

At CB HYMAC, we employ more than 60 trained technicians to help service your machine at the premier standards of Caterpillar. We follow strict contamination regulations and testing guidelines to guarantee our finished product is performs at optimal levels.

Interested in learning more about our CB HYMAC machine shop division and its services? Contact Cleveland Brothers or visit our CB HYMAC website.

Welding Services

As a division of Cleveland Brothers, CB HYMAC carries the same dedication to maintaining the highest-quality standards in the industry. Our certified welders are capable of welding on carbon, copper, alloy steels, stainless and aluminum.

We offer reconditioning services for a range of expensive components at lower prices compared to purchasing new products. Our computer-controlled, automatic burning tables are also capable of cutting carbon steel plates up to 6 inches thick. CB HYMAC welding services recondition components to equal or better standards compared to new parts.

Our welding salvaging operations include:

- Transmission-shaft-surfaces

- Rear-differential-trunnions

- Pump-shaft-seal-surfaces

- Yokes

If you are searching for experienced welders and modern technology methods to repair your heavy equipment’s worn or broken components, visit CB HYMAC.

Fabrication Services

Our commitment to ensuring a competitive, quick and effective job in repairing your heavy equipment parts at Cleveland Brothers transfers to our CB HYMAC division as well. We provide turnkey services for all of your fabrication needs. Our in-house engineering and design assistance services produce rapid turnaround, competitive pricing and of course, high-quality standards.

When your equipment needs exact specifications to get the job done, CB HYMAC is your expert partner for custom fabrication. We can design and produce custom fittings to meet precise requirements for any project. Our state-of-the-art facility offers advanced pattern cutting, CNC machining and CNC welding services making us a full-solution fabrication shop centrally located in Pennsylvania. Drop off your equipment at any Cleveland Brothers location for easy and convenient transporting to CB HYMAC in Harrisburg, PA.

The custom fabrication shop of CB HYMAC provides you with exceptional turnkey services. Learn more information about how CB HYMAC can service your fabrication needs.

Chroming and Polishing Services

As a full-service hydraulic cylinder shop, CB HYMAC is able to rebuild, repair, re-chrome, re-tube and fabricate cylinders, including all models of industrial and commercial applications. We provide the following chroming services:

- Re-chrome parts up to 38 feet by 22 inches in diameter

- Hone up to 25 inches in diameter

- Repair chrome spots without total re-chroming

- Genuine HYCO telescopic cylinders are available to CB HYMAC clients

The CB HYMAC division offers genuine HYCO telescoping cylinders, which are the most premium products on the market. HYCO cylinders have increased impact and scratch resistance as they’re designed with alloy steel tubing. These genuine cylinders produce lower running friction, while also having a U-cup design and alloy tubing material.

Chrome refinishing increases the corrosion life of your industrial or heavy equipment parts without affecting their mechanical properties. The CB HYMAC industrial re-chroming process can also increase the hardness of a component, which adds a greater wear resistance. Chrome plating increases not only the mechanical properties of your hydraulic cylinder components, but also the physical properties.

To learn more about CB HYMAC chroming and polishing services, check out our CB HYMAC website.

Repair and Resurfacing Services

Your heavy equipment or industrial machine relies heavily on powerful hydraulics to perform at optimum levels. And like any main component, the hydraulic system is sensitive to dirt and debris. When contaminants build up on your machine’s parts, hydraulic resurfacing is essential in maintaining a reliable and safe operation.

Hydraulic repair technicians at CB HYMAC, a division of Cleveland Brothers, can repair and remanufacture cylinders, pumps and motors. We can custom-build your heavy equipment cylinders to fit your exact application, or we can salvage your machine’s worn or damaged components. Our trained professionals will ensure a high-quality service while saving you time and money.

We leverage our knowledge and expertise of Caterpillar, the world’s leading heavy equipment manufacturer. Our machining shop at CB HYMAC offers the industry’s best CNC equipment and Cat exclusive technology. As a result, CB HYMAC provides better wear-resistance, increased component life and faster application times.

Our qualified technicians and machinists have in-depth experience to help repair your heavy equipment components. They are trained to find each faulty source and to develop an effective repair strategy. Before returning your machine, CB HYMAC thoroughly tests its working performance for accuracy.

If you are searching for a cost-effective and exceptional service for your hydraulic resurfacing or repair needs, contact CB HYMAC today!

Fluid End Manufacturing

CB HYMAC provides fluid end machining for your heavy equipment and industrial machinery in your milling, drilling or threading jobs. Directional drilling critically relies on fluid ends to regulate the fluids being pumped into the well for oil fracking. Because fluid ends play a critical role and perform for consistent regulation, the components only last about several weeks — and in some cases, several days.

We leverage our extensive experience in the oil and gas industry. Over the years, we’ve mastered designing custom fluid ends of any size for any application. Our in-house engineers will work with you to create a fluid end that meets OEM specifications to run at optimal performance. Made from solid blocks of steel, fluid ends require large amounts of machining. Although fluid ends may pose machining challenges, such as raw material scale, varying depths of cut and long tool overhangs, CB HYMAC professionals are trained for the job.

The phases of fluid end manufacturing are:

- Cutting and Cubing: The cutting and cubing process involves squaring rough billets and prepares the block for rough machining.

- Rough Machining: Rough machining is a phase that optimizes your machine’s operations and provides high metal removal rates.

- Finish Machining: The process of finish machining encompasses threading operations.

Our fluid end manufacturers are trained in-house to provide you with the highest-quality manufacturing at cost-effective rates. To learn more about fluid end manufacturing at CB HYMAC, check out our website.

Power End Rebuilds

Power end rebuilds deliver new life to old equipment to maximize durability and value. Cat machines are “built to be rebuilt,” and the process delivers a cost-effective solution compared to purchasing new components.

The power end rebuild process involves the following:

- We thoroughly inspect your part and provide an accurate quotation.

- CB HYMAC disassembles your machine and components.

- Our factory-trained technicians use specialty tools to reassemble products by standards set by Cat.

- The process involves painting, re-identification and warranty.

Our power end rebuild program at CB HYMAC is Cat certified, and our technicians incorporate modern technology and engineering updates. The outcome will increase your engine’s efficiency, fuel economy and performance. Our CB HYMAC division guarantees a cost-effective rebuild to save you time and money. We put our high-quality standards in place to assure you exceptional service. Learn more about the power end rebuild procedure CB HYMAC offers.

Hydraulic Component Rebuilds

To give your Cat machine a run at its “second life,” CB HYMAC facilitates in rebuilding your undercarriage and track components. We perform component rebuilds in-house by Cat factory-trained technicians. By rebuilding parts of your heavy equipment or industrial machine, its lifespan will increase for a fraction of the cost compared to total replacements.

Component rebuilds include:

- Final drives

- Transmissions and converters

- Differentials

- Piston pumps and motors

Our Rebuild Center employs trained technicians in heavy equipment component rebuilds, as they integrate modern technology and the most up-to-date techniques.

The component rebuild process involves the following steps:

- CB HYMAC cleans and prepares components for assessment.

- We thoroughly test components using modern technology.

- Techs disassemble and inspect all parts.

- We re-assemble with replacement or reconditioned parts.

- We complete final testing of rebuilt components to ensure high standards.

All component rebuilds obtain the quality, contamination control and safety standards of Caterpillar. CB HYMAC offers rebuild options such as:

- Cat-certified rebuild

- Cat power train rebuild

- Cleveland Brothers second life rebuild

- Cleveland Brothers power train rebuild

- Powertrain rebuild

- Cleveland Brothers custom rebuild

Our different rebuild options have the potential to save you between 40 to 75 percent of the cost compared to new replacement machines. Sounds like a good deal, right? A deal that provides you a cost-effective solution while maintaining high standards of completion. If you are searching for more information about our machining and hydraulics division, check out CB HYMAC.