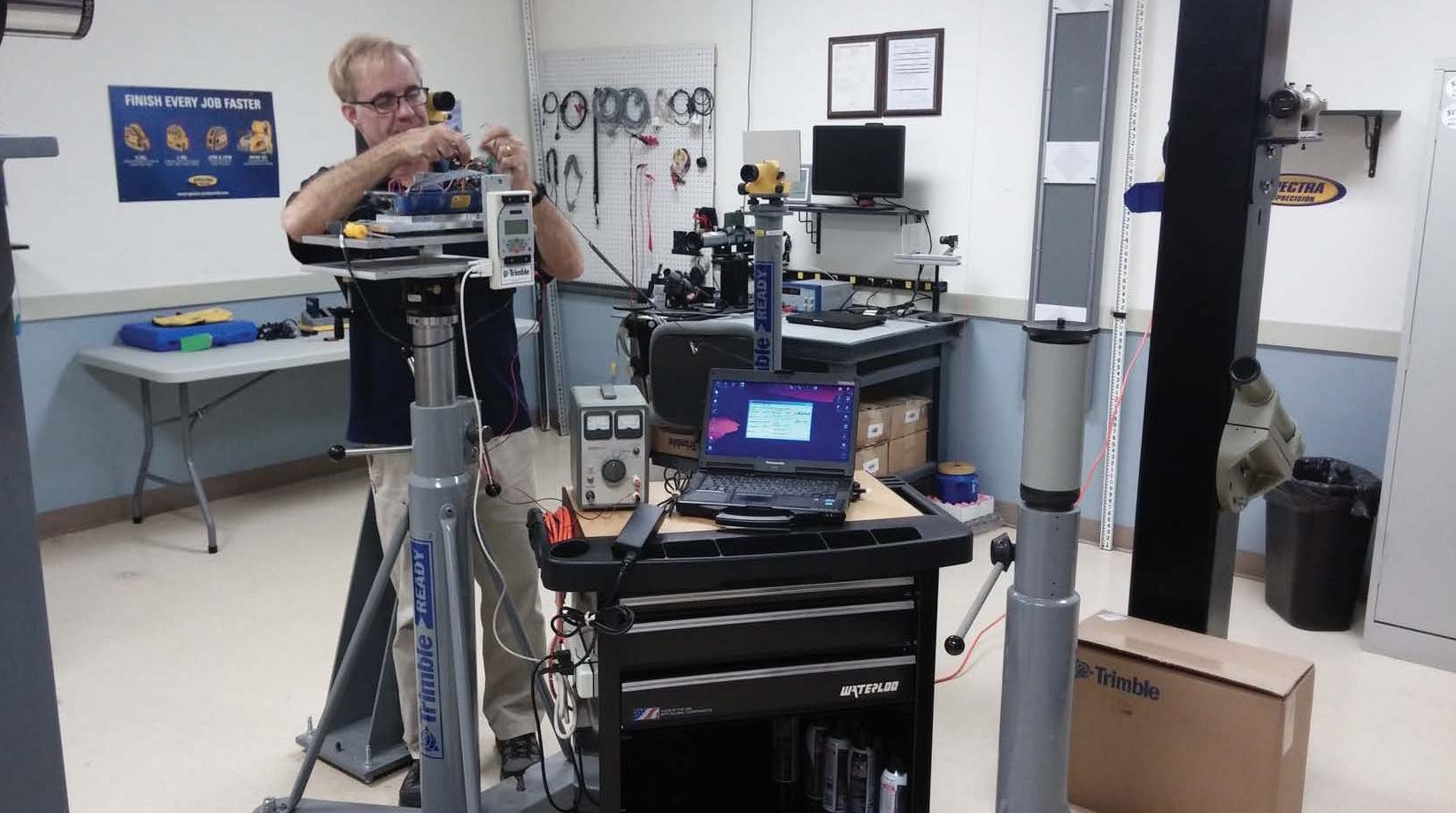

Calibrating your instruments, is it really that important?

In the construction industry, keeping your instruments calibrated is a must, especially in today’s world where jobsite surveying instruments tend to have more electronic components than ever before. This causes them to be at a higher risk of becoming uncalibrated especially if they are dropped or bumped.

Recommended by most manufacturers, optical and laser instruments should be calibrated every six months to maintain the accuracy of your instrument and increase the quality of your work.

Although your instrument might not seem like it needs to be calibrated, the risk of having to do rework can be higher than the cost of the calibration itself. Calibration is a paid maintenance service that should be done on a semi-annual basis much like getting an oil change or inspection on your car.

Using an grade laser or level that hasn’t been properly calibrated can waste time, and we all know time is money.

Regular inspection can prevent your instrument from failing and causing costly downtime and other disruptions. Calibrating regularly produces a consistent quality in your work and also keeps your employees safe when working with heavy equipment.

If your product fails, your customer will want the job redone for free, potential customers may no longer see you as a reliable resource, taking their business elsewhere and your employees could be injured on the job leaving you to pay workers compensation.

Now through September 30, 2017, buy a qualifying instrument and get your first calibration free!

If you have further questions about calibrating your machine or to schedule a service on any of your instruments, contact SITECH Allegheny at 855-417-0290.