Customer Feature: Troegs Brewing Company

IT TAKES A LOT OF AIR TO MAKE A GOOD BREW

Every aspect of beer brewing relies on compressed air, and Troegs Brewing Company chose a Sullair compressor from Cleveland Brothers for a major expansion that promises a tasty supply of suds for decades to come.

“The brewhouse, filtration, cellaring and kegging, along with every piece of equipment in the bottling room, requires compressed air,” said Jason E. Knox, maintenance manager of Troegs Brewing Company, Hershey, PA.

In October 2011, the increasingly popular Troegs made a big move, leaving its original 30,000-square-foot converted warehouse and building a new 90,000-square-foot brewhouse and tasting room in the heart of Hershey, Pa.

Growth was meant to accommodate a never-ending stream of visitors and expand capacity to meet growing demand. The old space was so cramped that brewing sometimes had to stop during tours. With expansion came the need for more compressed air. The old brewery’s 15-hp reciprocating compressor and 20-hp rotary screw compressor “would have been much too small to handle the new demands of the brewhouse, filtration and cellaring operations here in Hershey,” said Knox.

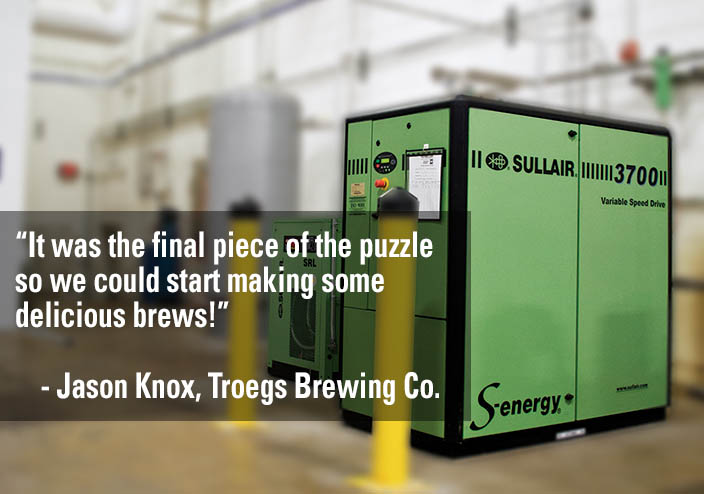

Troegs chose to install a 3709 V/A model compressor with variable speed drive in the new facility. The unit met all requirements for air consumption, and service and parts were easily available from Cleveland Brothers, headquartered just a few miles away.

“In our continued efforts to lessen our carbon footprint, the variable speed drive and the overall efficiency of the air-end with the low restriction inlet valve made sense,” said Knox. “It also has a very small footprint and is extremely quiet.”

The unit was installed with all the brewing equipment in September 2011.

“It was the final piece of the puzzle so we could start making some delicious brews!” Knox said.

LET THE BREWING COMMENCE

Brothers John and Chris Trogner sold their first bottles of Troegs beer in 1997 from batches brewed in a Harrisburg warehouse. Today, they brew and distribute 40,000 barrels in total volume throughout Pennsylvania and most surrounding states. Its holiday Mad Elf ale is so popular that distributors often sell half their shipments through pre-orders.

From the beginning, visitors have trekked to Troegs for tours and tastings. Offerings include seasonal beers – this year’s pumpkin beer was Troegs’ first, brewed from local gourds – and its famous one-time brews known as “scratch” beers. The new site, with its tasting room and snack bar, complements Hershey’s world-class attractions that include Hersheypark, shopping outlets, concerts and special events.

“We’re just a hop, skip and a jump away from all that activity,” said Jeff Herb, Troegs media director. “It’s a destination brewery. Come in, sit down, eat some food, have a couple of pints.”

The Sullair compressor behind all the brewing activity recently passed the 8,000-hour mark and has run flawlessly. At its first major service, everything looked great.

“With all of the moving parts that make up Troegs Brewing Company, it is nice to know that one of the main arteries of this facility is working well and is well taken care of,” Knox said.

He adds that Cleveland Brothers has been instrumental in servicing and maintaining the compressor.

“From the initial sales staff to the service manager to Tony, the technician; we have been very happy and confident with our purchase. When the time comes for another expansion, we will definitely be calling on Cleveland Brothers to spec out our air needs,” he said.